Borehole Flushing: What Causes Siltation & Why You Need It

At Nakiso Borehole Drilling, we once completed an interesting project where our client suspected the aquifer was running dry, but the problem was something much simpler: silt.

Due to the location of the site and knowledge of the ground conditions, we suspected that the fault was more than likely due to the PVC bore screen having become blocked and silted up.

|

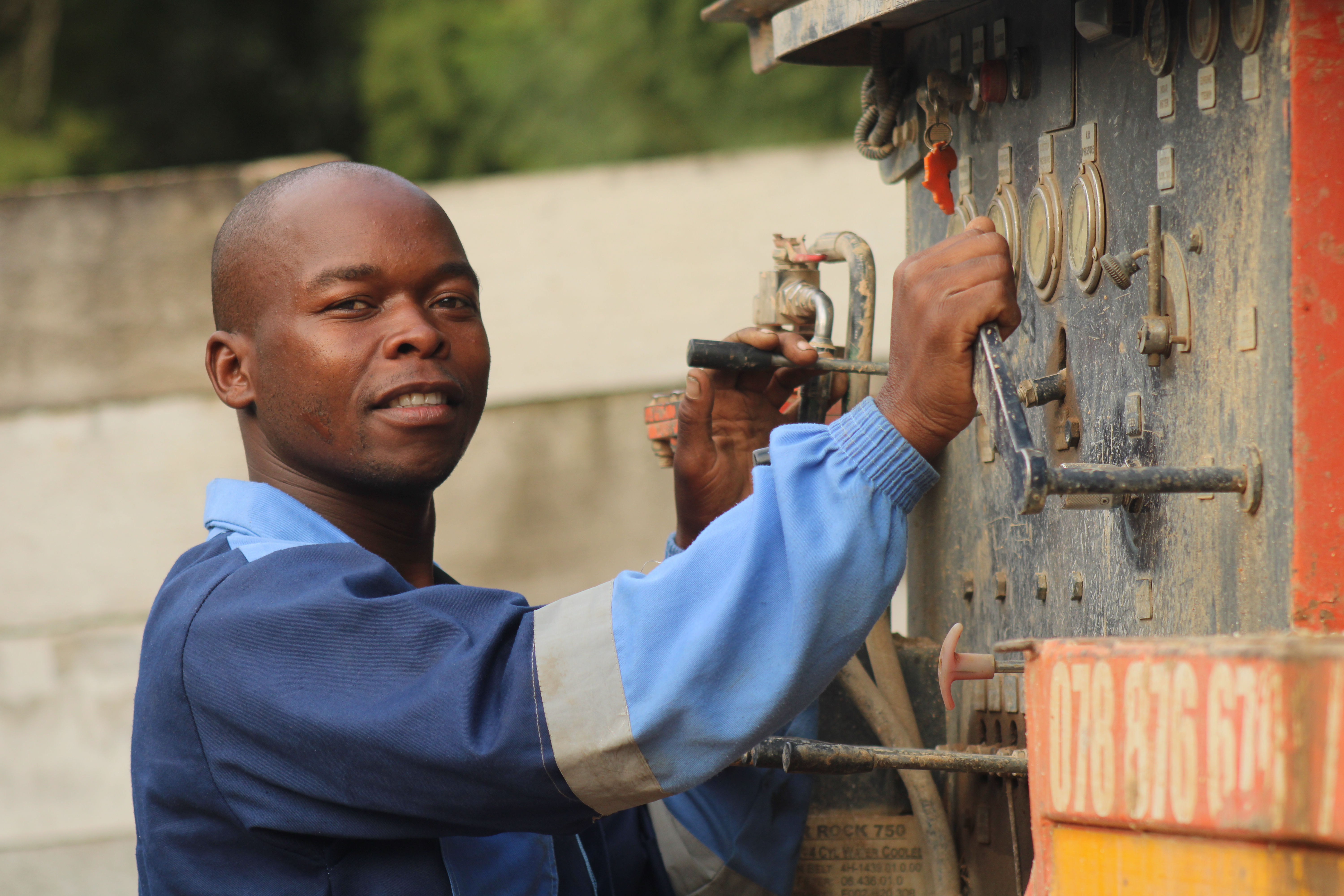

| Restoring borehole yield through professional flushing. |

A Case of Mistaken Drought

So once our client had contacted us, with our Operation Manager's vast knowledge of hands-on engineering skills, he devised a method to desilt the bore and clean the bore screen section. As soon as our engineers arrived on site they immediately realised that our suspicions were, in fact, correct, as all around the borehole entrance and surrounding area was a fine film of silt.

Once this process was completed a new pump was installed and the bore test pump. Our client was ecstatic as they had started to consider that it was going to be necessary to drill a new borehole water supply.

What is Borehole Flushing?

Borehole Flushing is needed when the pores of the aquifer inside the borehole get clogged by silt and sand-sized particles or mineral deposits. This reduces the permeability of the aquifer making it difficult to pump water, thus reducing the water yield.

Cleaning The Aquifer

Over time, prolonged usage or specific geological factors can cause particles to clog the water entry points. Flushing clears these obstructions.

Improving Quality

These particles not only deter flow but may also change the water's odour, colour, or taste. Removal is essential for both yield and quality.

|

| Enjoy clean, boosted water yield for years. |

How Nakiso Restores Your Flow

At Nakiso Borehole Drilling, we use high-pressure water injection procedures with advanced air compressors and flushing tools.

Compressed air is passed into the borehole clearing out all the silt and sand, raw dust, decayed particles, mineral deposits, and other extraneous particles that are causing the borehole to clog.

The borehole flushing process is continued until all the particles are cleared and a clean stream of water is pumped out of the borehole. After a borehole is thoroughly flushed you can enjoy a clean and boosted water yield that continues for years.

Experiencing Low Yield?

If you are experiencing similar problems, contact us for further advice. We would be more than happy to offer our flushing services.

Chat With UsAbout Nakiso Borehole Drilling

At Nakiso Borehole Drilling, we are your comprehensive partner for unlocking reliable water on your property. Our highly skilled team tackles all drilling projects, from standard boreholes to specialized Blast Hole and RC Drilling.

We handle everything in-house for a seamless experience, encompassing expert borehole siting, efficient drilling, and pump installation – solar, electric, or manual – tailored to your specific needs. With Nakiso, your reliable water source is just a drill away.

We don't just strive to be the best; we maintain the industry's strictest quality standards and are committed to sustainable practices for the future of Zimbabwe's water security.

Fact 1: Know Your Borehole Casings

The Preferred Borehole Casing In Zimbabwe Is Class 9 and 10 (Pressure Classes.)

This is because Class 9 and Class 10 Casings are more collapse resistant. The strength of a Casing is often described as collapse resistance.

Fact 2: Borehole Drilling Depth

The exact depth, of where the water is located, cannot be established by the drilling contractor nor the Water Surveyor (Borehole Siter).

Fact 3: There Is No 100% Guarantee

It is important to note that it is never a 100% guarantee that any hole will yield water, the amount and water quality can also not be guaranteed by the drilling contractor and water surveyor.

Fact 4: Siting Is Important

Making use of a hydrologist or traditional water diviner will increase your chances of having a successful borehole that will yield a sufficient amount of water.

Fact 5: Know The Risks

The risk of the borehole drilling lies with the property owner. The client will still be liable for the drilling costs irrespective of a borehole yielding water or not.

Our Branches and Our Contacts

Churchill Ave Branch

Business Offices (HQ):55 Churchill Avenue,

Alexandra Park,

Harare North,

Zimbabwe.

Call Us Today:

Office Numbers: +263 867 71 88844

Sales: +263 78 860 8009

Operations: +263 78 860 8005

Marketing: +263 78 876 6701

Email: info@nakisoboreholes.co.zw

Website: www.nakisoboreholes.co.zw

Bluff Hill Branch

Business Offices:36 St. Anthans Drive,

Bluff Hill,

Harare,

Zimbabwe.

Call Us Today:

Office Numbers: +263 71 494 0883

Sales: +263 78 860 8009

Operations: +263 78 860 8005

Marketing: +263 78 876 6701

Email: info@nakisoboreholes.co.zw

Website: www.nakisoboreholes.co.zw